Kingred Large Wire Cut EDM KD700ZL

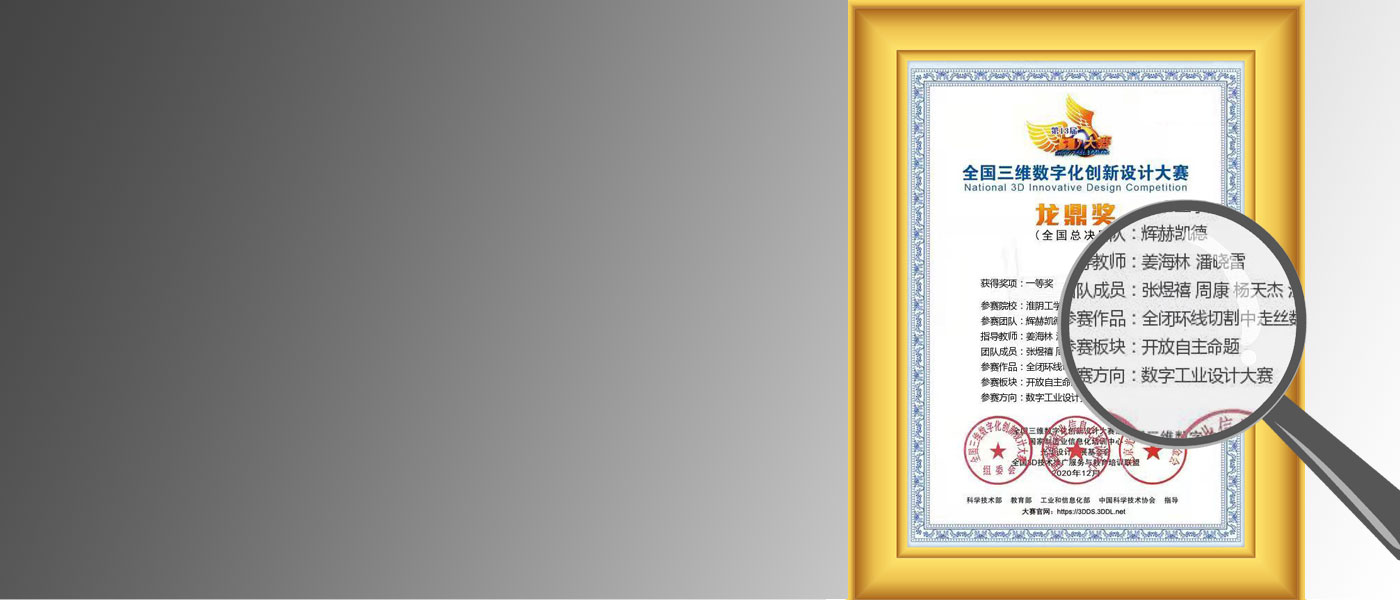

ZL machine won the National Finals Long Ding Award of the National 3D innovative Design Competition.

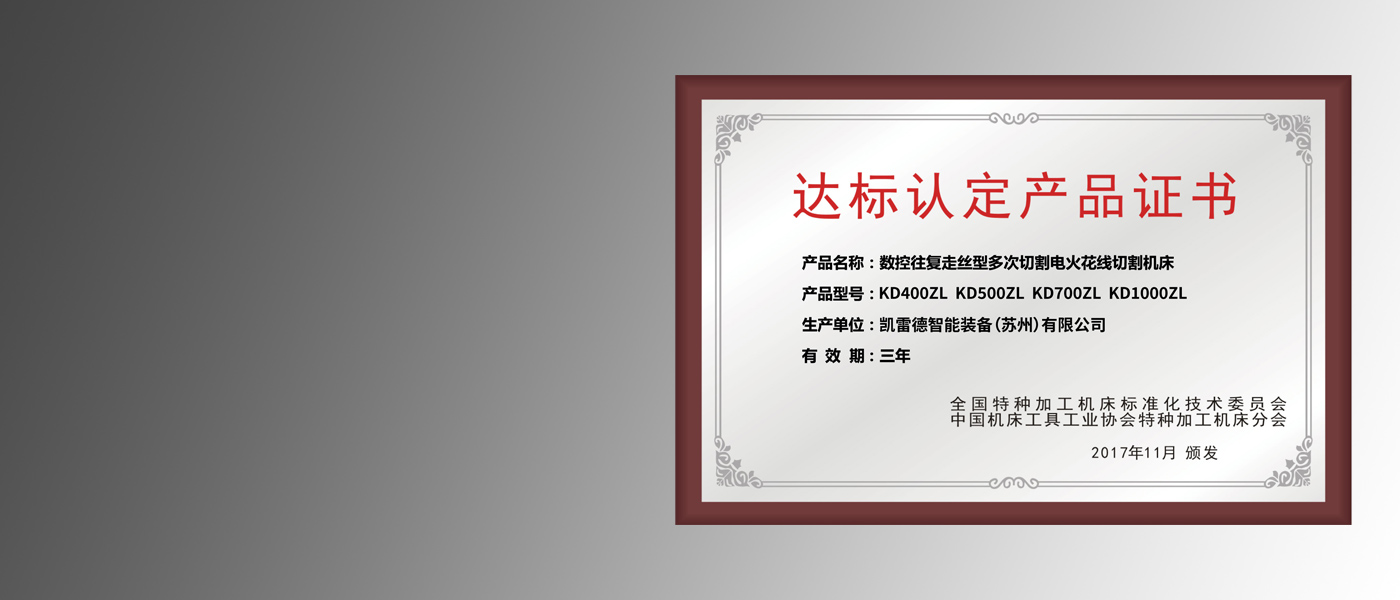

Special machine tool branch of ChinaMachine Tool& Tool Builders Association Qualified product ofcertification.

Servo Motor Drive, Absolute Encoder Positioning.

PLC Control, Long-lasting Stability,Extremely Low Failure Rate.

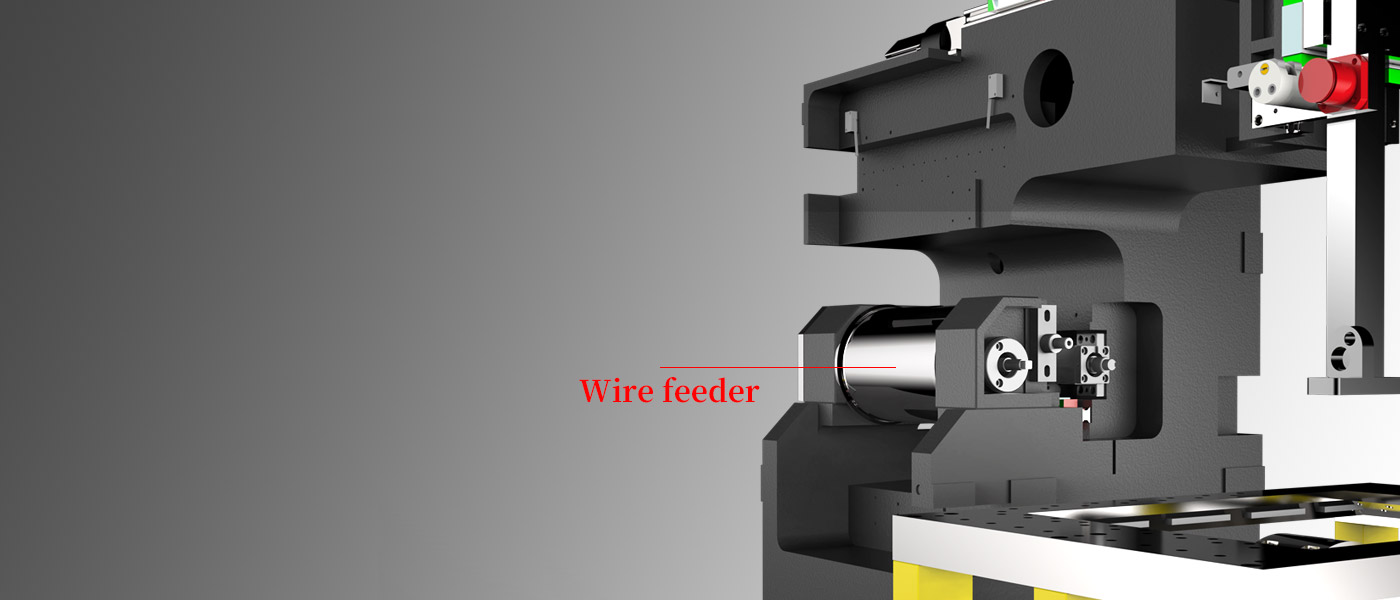

Creative Design Wire-feed Structure.

6-axis CNC.

Servo Wire Cut EDM KD700ZL Parameters

| Unit | Parameter | |

| X*Y travel | mm | 550X700 |

| U*V travel | mm | 60X60 |

| Worktable size | mm | 710X950 |

| Machining parameters | ||

| Cut accuracy straight/taper | mm | 土0.005/土0.015 |

| Cut taper | °/mm | 土10/80 |

| Cut speed | mm /min | 260 |

| Cut surface finish | μm | Ra≤0.8( Material: Cr12 Thickness:20mm pl2mm 1+3 cuts) |

| Cut current | A | 9 |

| Payload | kg | 800 |

| Cut thickness | mm | 280 |

| Min drive | mm | 0.001 |

| Wire Parameters | ||

| Diameter of wire | mm | Φ0.10-Φ0.25 |

| Wire feed travel | mm | 280 |

| Wire tightening type | CNC tighten wire | |

| Length of wire installed | m | 300 |

| Basic parameters | ||

| Rated power | Kw | 3 |

| Input voltage | V/Hz | 380/50 |

| Weight of machine | kg | 4000 |

| Outer size | m | 2.4*2.1*2.2 |

| Packing size | m | 2.6*2.2*2.4 |

| Tank parameters | ||

| Capacity | L | 120 |

| Filtering type | High pressure multi-stage filtration | |

| Packing size | m | 0.7*0.7*0.8 |

| Outer size | m | 0.9*0.8*1.0 |

| G.M/N.M | kg | 80/60 |

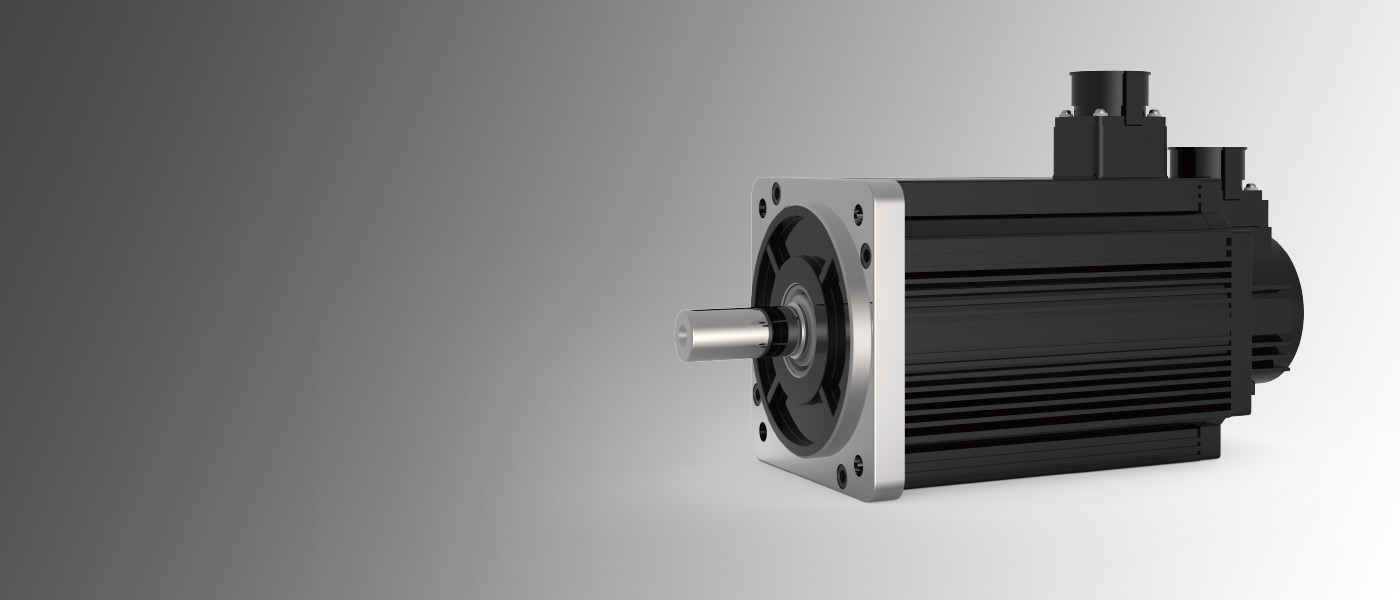

1、Servo Motor Drive

X/Y-axes of ZL series used Kingred depth customization R&D Servo Motor that could realize high precision positioning to resolve the shortcomings of stepping motor, which dramatically increased machine accuracy. Furthermore, its speed is fast. Kingred matches good development needs through self-development.

Apply DSP+FPGA algorithm.

Better suited to WEDM machining features.

High precision, avoid risks.

High-speed response, High precision.

Moment of force more stable than stepped motor.

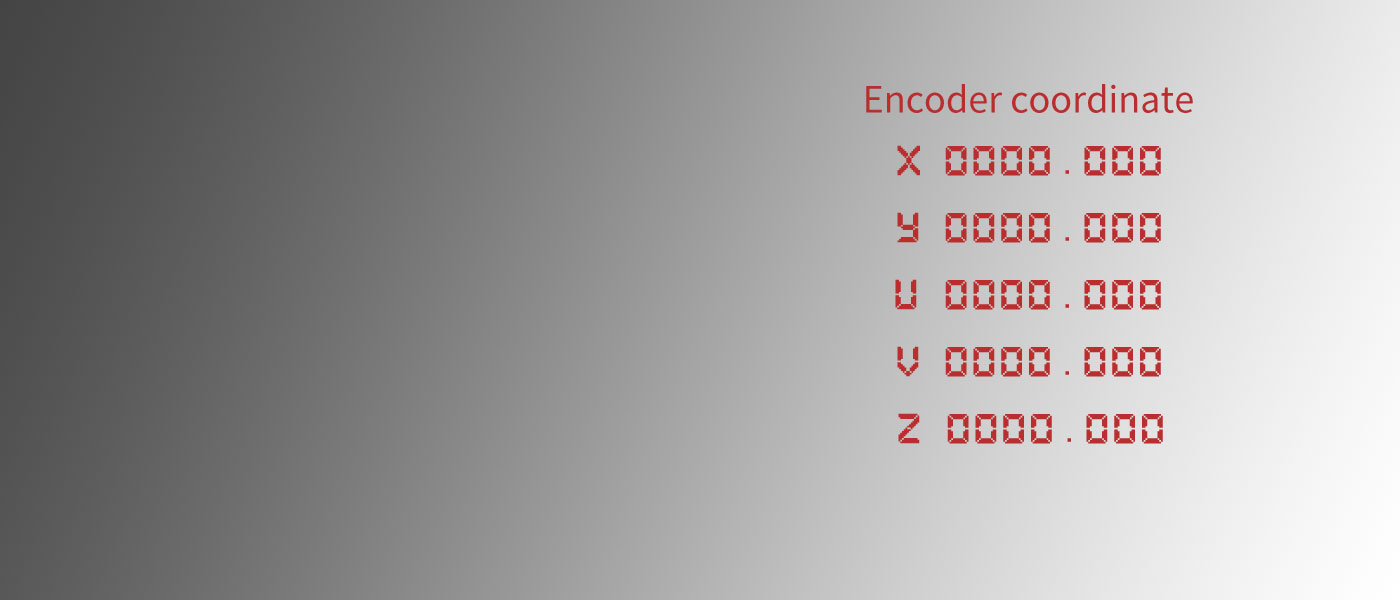

2、Absolute Encoder Positioning

Absolute Encoder could directly transmit information to the machine and could provide super precision position to machining. It needn't come back and ensure information in time due to directly transmitting position.

Absolute Encoder Positioning.

Transmit current absolute position.

No need to reset.

Instantaneous response.

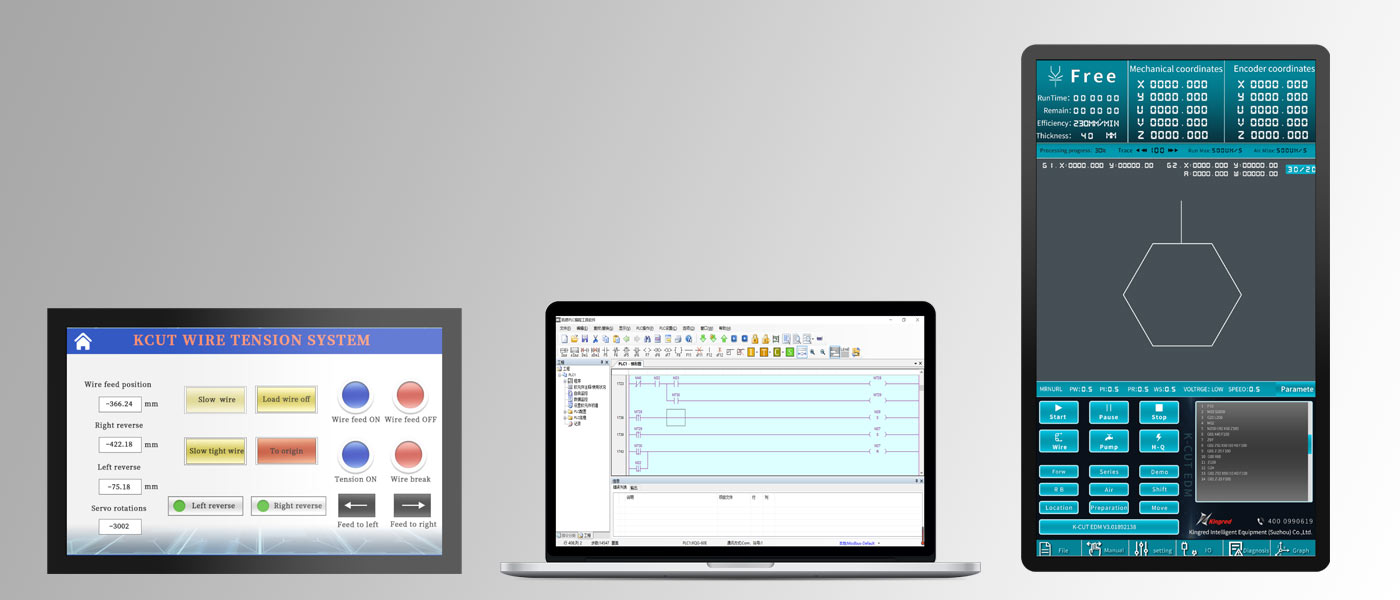

3、PLC control super-low fault rate

Machine control system uses PLC control model that has high stability, low fault rate, high expansibility, and accommodates industry environment. PLC fits special machining by depth R&D.

PLC independent Central Processing Unit data instruction response more timely.

PLC super-strong stability, adapt complex manufacturing environment.

Super-strong expansibility, realize future upgrade or flexible customization.

Upper computer network transmission,more stable signal.

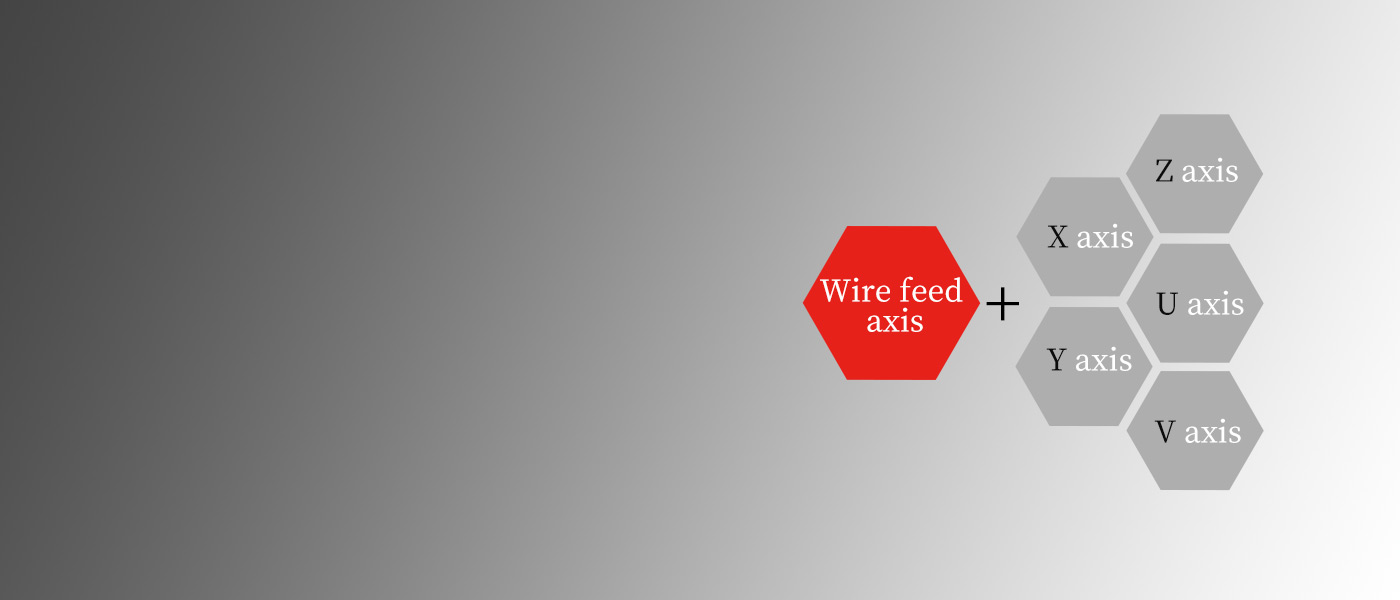

4、6-axis CNC

The X, Y, U, V, Z, and wire feed axes are fully CNC, with higher jumping precision, convenient operation, and more accurate position and control.

Achieve it in one step.

CNC operation more precisive.

Automatically working.

Achieve it in one stepNo need people to control.

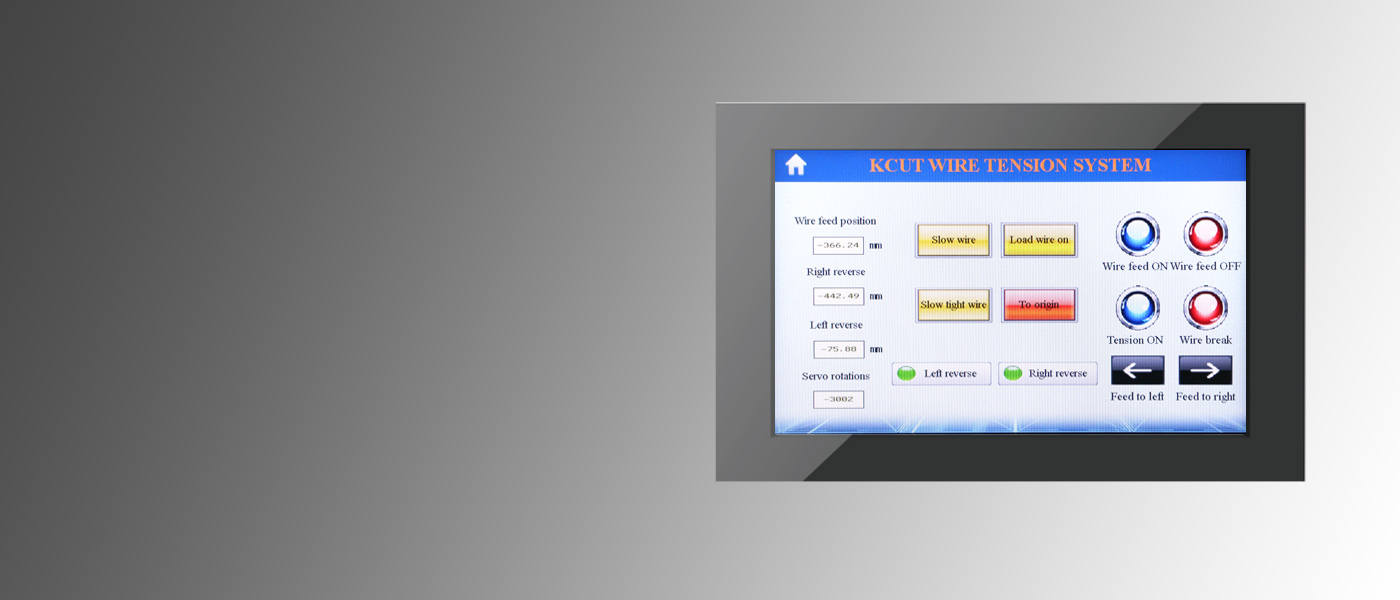

5、One-key CNC tighten wire

Kingred independently creates tighten wire and cooperates Kingred K-Cut Wire system, which reaches wire feed digitization.

Easy to operate.

No need to use auxiliary tool.

No need to use tighten wheel.

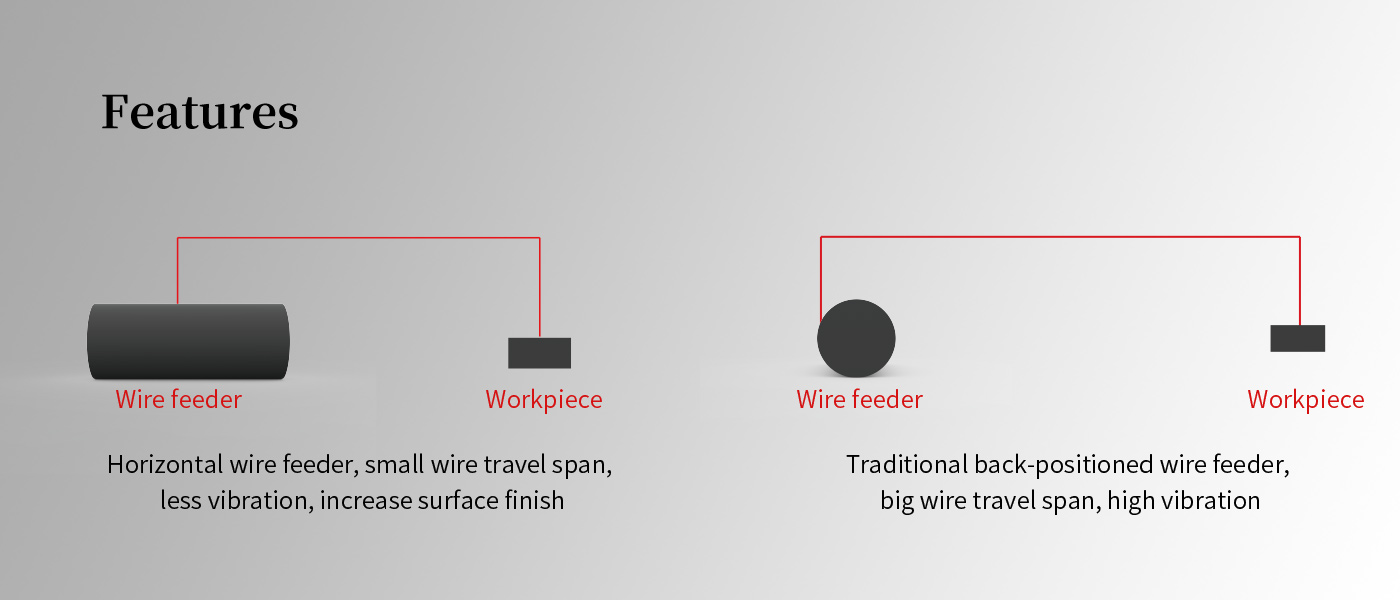

6、Horizontal wire feeder vibration reduction, surface stripe obvious reduction

Kingred designs wire feeder that has small travel span, workpiece stripe reduction, and surface finish increase.

Kingred patent design.

Small wire travel span, less wire vibration .

Unobvious surface stripe.

Fixed wire feeder to avoid affecting accuracy.

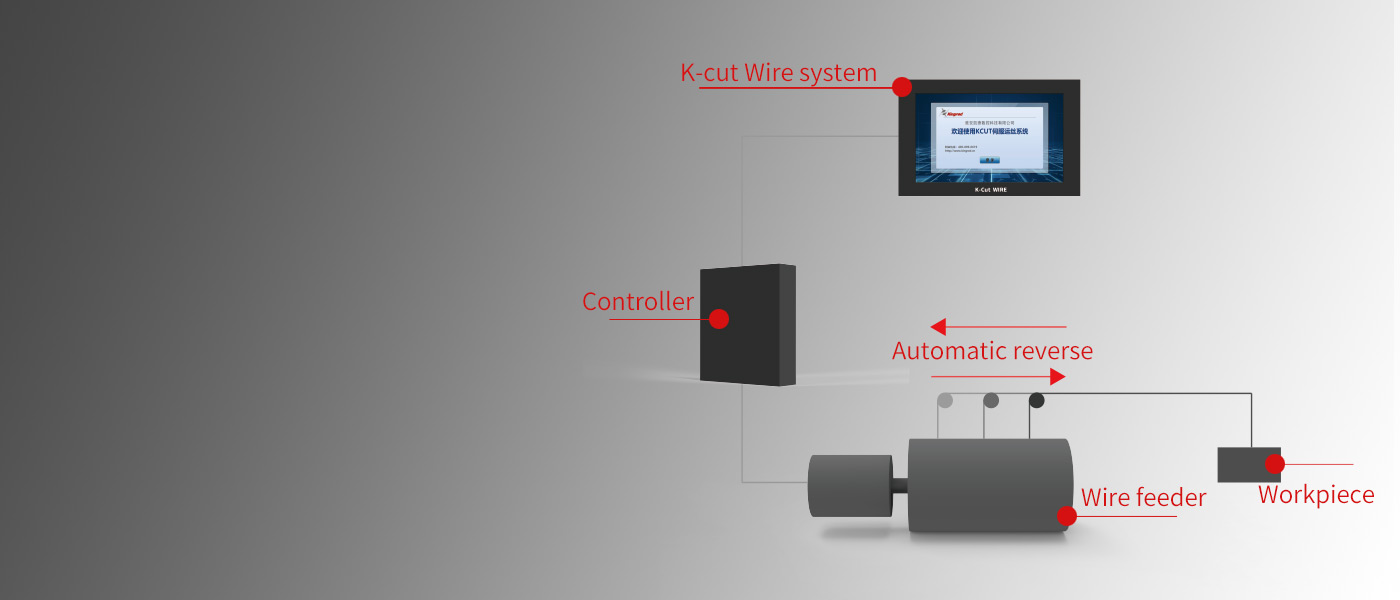

7、Automatic direction reverse system

Kingred K-CUT Wire feed system realized automatic reverse and the foundation of intelligence.

Automatic reverse

No need to press the button

Customize the reversing position

Digital control avoids reverse failure

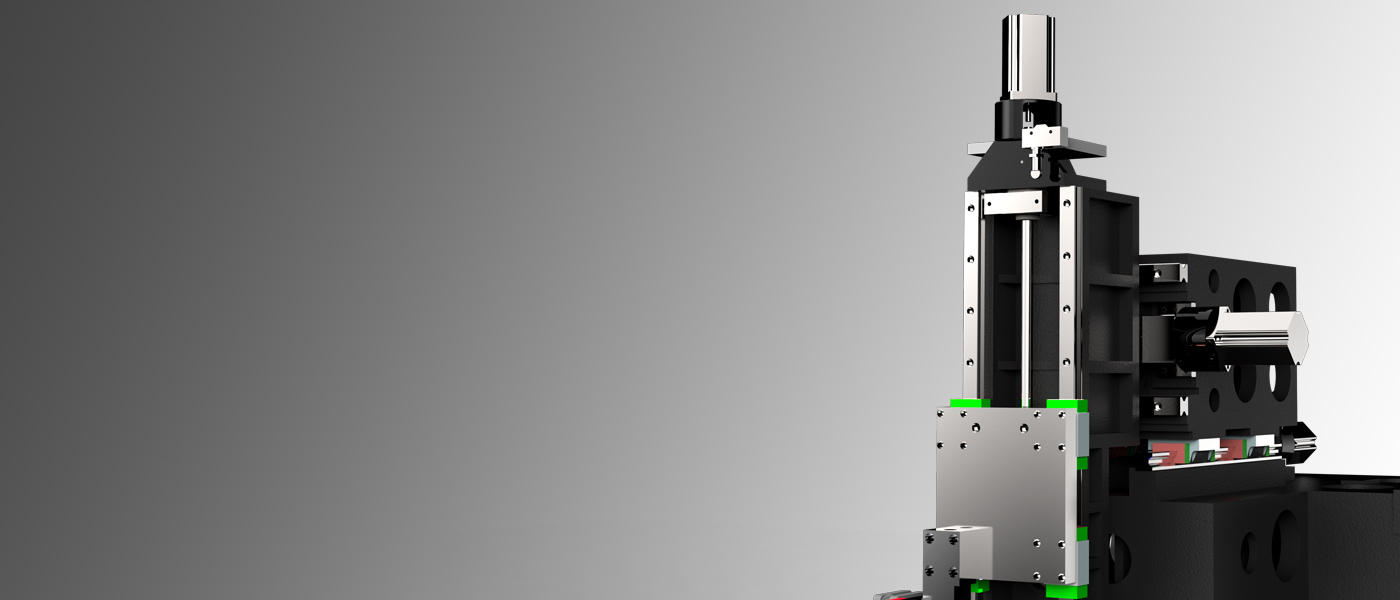

8、Stable taper structure

Kingred creation develops independent taper module, realizing ±12°large taper machining, 120mm the support of full travel of double line rails, and taper machining precision and surface finish are significantly improved compared with the market small taper structure.

Independent taper module hardware design

Z-axis double guideway machining great stability.

Support Z-axis memory height setting

Taper up to ±12°

Independent U/V-axes model

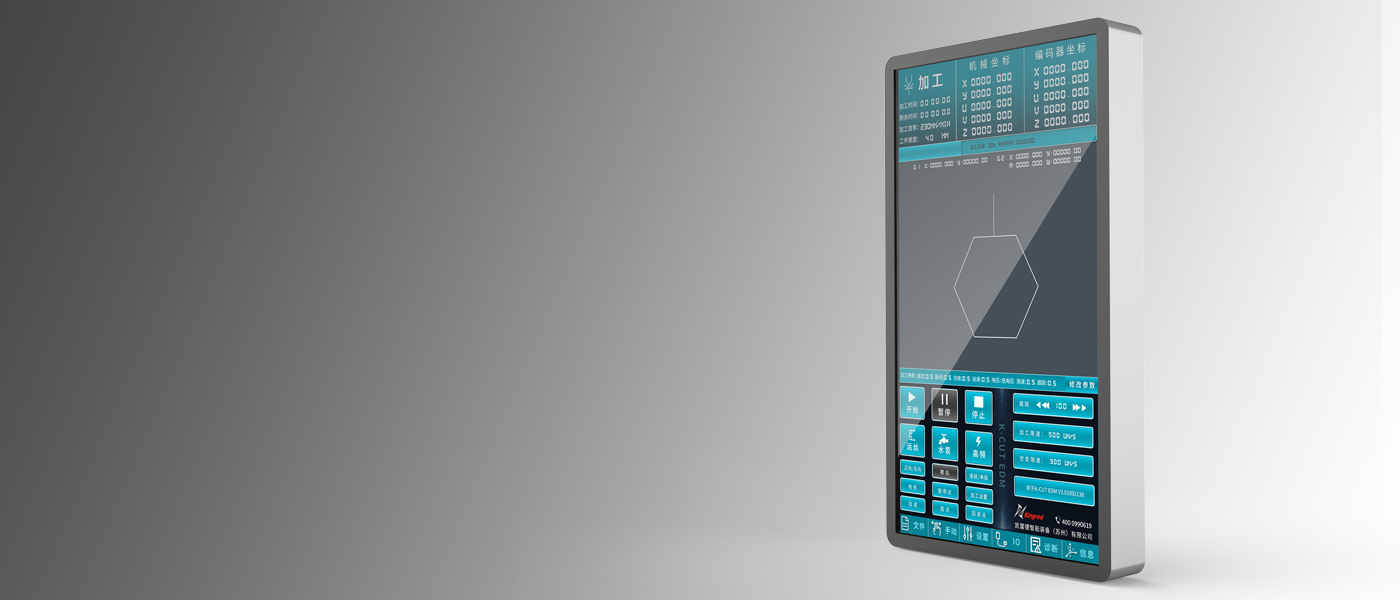

9、21.5-inch big touch screen, touch screen age coming

Location operates more precisive, home screen shows parameters, no need to inside check.

Clear screen

Obviously main parameter

Dual input methods

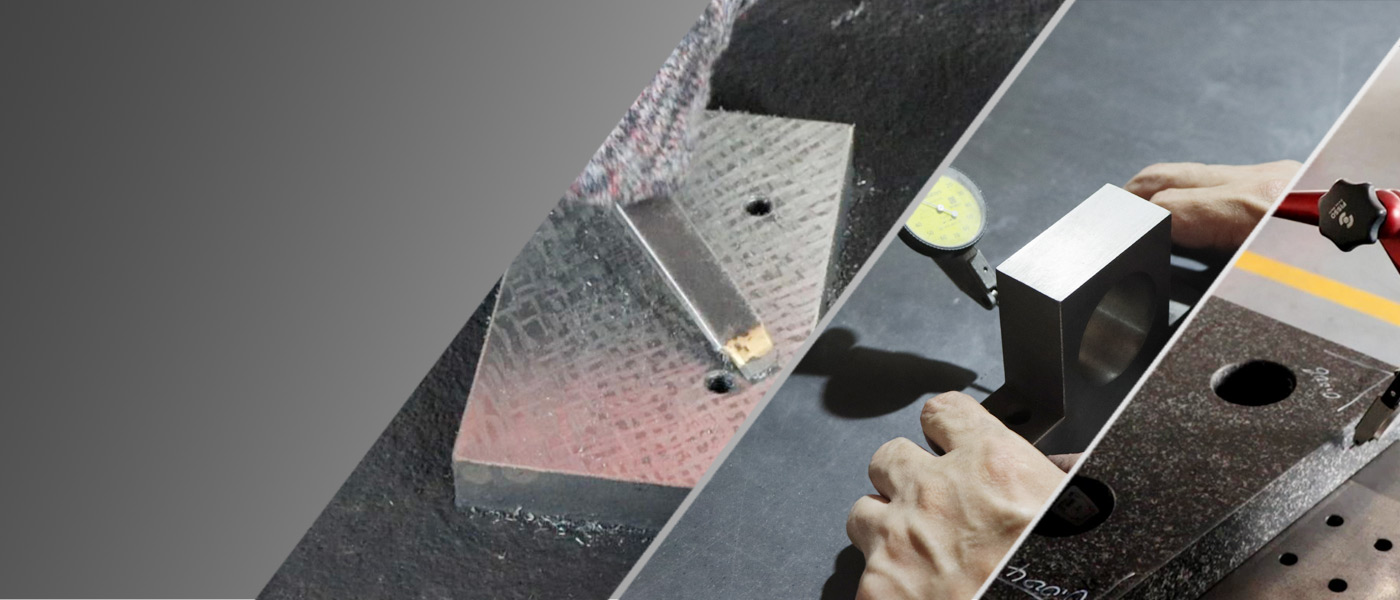

1、Casting

Based on H250 international standard casting, Kingred developed metal ratio to improve casting rigidity and extensibility. All casting passed two times tempering and 3-6 months of natural aging treatment to release inner stress and decrease deformation.

H250 material + Unique rear metal.

Two times tempering/Natural aging treatment vibration aging.

Thoroughly remove internal stress.

High rigidity and stability.

2、Guideway

Sliver 1.5µm SP grade linear guideway realized high precisive position and repeated position to ensure machine height machining stability and precision, load rigidity.

1.5µm super precision.

Super stability and precision machining.

High-load rigidity.

Ultra-precision guideway.

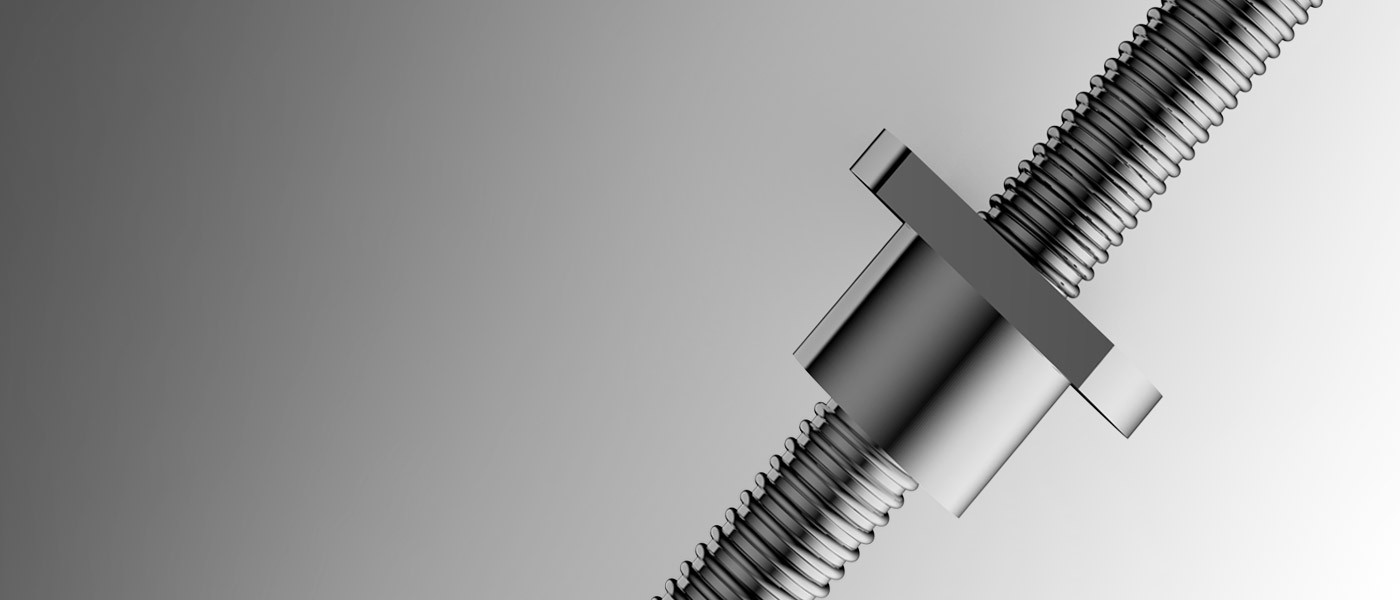

3、Ball screw

P grade ball screw, high-precision ball screw could realize high-precision movement and low friction rate to improve machining efficiency.

P grade ball screw.

Nan craft P grade ball screw.

High-precision movement.

Extremely low friction coefficient.

4、K-Cut series software intelligent manufacturing

Kingred built ecologically intelligent manufacturing chain, integrating three software K-Cut EDM system, ''K-Cut Wire'' management system, K-Cut PLC system to create a future.

Kingred built ecological intelligent manufacturing chain, integrating three software K-Cut EDM system, ''K-Cut Wire'' management system, K-Cut PLC system.

5、K-Cut EDM system

K-Cut EDM is Kingred independently produced Wire Cut machining system. Graphical drives program, easy to operate. AR Measurement of Slant Edge, Finding the center of a circle, Compensation of Screw Pitch and other practical functions could improve operation. Inside intelligent auxiliary calculation is convenient to calculate kinds of machine deformation.

Self-production copyright, continuous upgrade.

Simple operation to decrease technician training cost.

Kinds of inside practical functions,ntelligent auxiliary calculation,ERP interfaces and remote management integration.

Multi-axis simultaneous machining to achieve complex workpiece manufacturing for taper, variable cone, upper and lower special-shaped.

6、K-cut WIRE system

K-cut WIRE system is an important part of Kingred K-Cut software ecology, which is responsible for wire feed system management. By combining hardware machine structure, it could realize wire digital management and kinds of feeding wire ways to reach convenience.

Wire visual data management.

Integrated one-key wire feeding, CNC wire tightening, digital reverse control, wire speed dynamic control.

Wire feed management takes the lead in realizing a new era of digital control and one-key convenient operation.

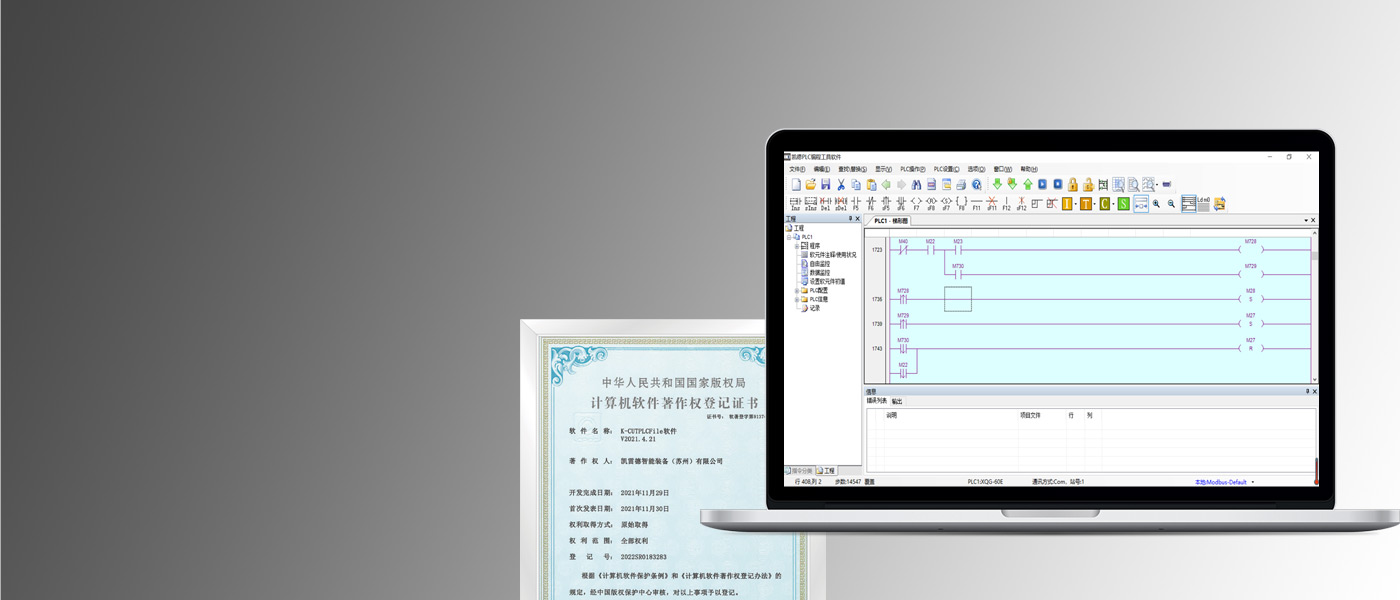

7、K-cut PLC system

K-cut PLC system is next next-generation intelligent manufacturing expander base, which is Kingred switch to PLC. All series of products applied PLC to replace traditional device. PLC digital processing program has high stability, low fault rate, high compatibility, and scalability, which is a key to keep creation.

Customized R&D for wire cutting special manufacturing.

Flexible manufacturing customization.

Prepare for next-generation manufacturing interface.

Intelligent manufacturing control entrance.

1、Whole process manufacturing chain

Kingred builds complete manufacturing chain, have perfect manufacturing chain for machining(rough finish, finishing, superfinishing),precise assembly, electric engineering, machine debugging,and process engineering, and realizes to independently finish from part to complete machine. Quality is run through each manufacturing process, builds three system of quality trace for people, product,process, and ensure the stability and consistency of product.

Machining

Precise assembly

Electric engineering

Process engineering

2、Advanced manufacturing equipment

Kingred continually completes and innovates the infrastructure of manufacturing equipment, ensures that hardware is high precision, successively introduces an advanced industry machine for Mitsubishi 5-axis machining center, SNK machining center, DMG machining center, OKAMOTO grinding machine.Industry lead manufacturing hardware equipment is basic guarantee that Kindred's machine has high precision and best surface finish manufacturing.

Mitsubishi 5-axis machining center

SNK machining center

OKAMOTO grinding machine

DMG machining center

3、Precise measuring equipment

Kingred have double inspection for manufacturing process and outcome, high precision measuring equipment for API laser inferterometer, Switzerland TEST three-coordinate detector, Germany Planolith marble square, Japan Sanfeng roughness tester,etc realizes from part precision to machine dynamic precision, positional precision and precise test of manufacturing outcome.

Laser interferometer

Toughness tester

Double zero-grade marble ruler

Three-coordinate tester

4、Ingenuity manufacturing process

Kingred with 17-year manufacturing experience have some experienced manufacturing engineers that working age over 5 years. Keep on connecting traditional craft and modern precise equipment manufacturing, the key high-precision parts adhere to the manual scraping process to ensure that the machine has a stable step distance machining precision for many years.At the same time, the human-centered quality traceability system creates an ingenious manufacturing process.

17-year manufacturing experience

Traditional technology application

Quality traceability system

-

Kingred edm hole drilling machine KD630CNC

Kingred edm hole drilling machine KD630CNC -

Kingred Hole Drilling EDM machine KD430CNC

Kingred Hole Drilling EDM machine KD430CNC -

Kingred Precision CNC WEDM KD400ZL

Kingred Precision CNC WEDM KD400ZL

Customers make us achievement

We will create value for you