Kingred edm hole drilling machine KD630CNC

Automatic Lifting Work Tank Door

X, Y, and Z Axes Driven by Servo Motors

Original Taiwan Rotary Head

Linear Motor Drive EDM KD400L Parameter

| Unit | Parameter | |

| X*Y*Z travel | mm | 500X600X400 |

| Distance of guide and working table | mm | 450 |

| Worktable size | mm | 780X550 |

| Machining parameters | ||

| Electrode range | mm | Φ0.2-Φ3.0 |

| Rotation speed of spindle (C-axis) | rpm | 0-60 |

| Max feed speed of spindle | mm /min | 120 |

| Control axis | 3 | |

| Max machining current | A | 3 |

| Max load of working table | kg | 2000 |

| Max cut thickness | mm | 400 |

| Min hole diameter | mm | 0.001 |

| Wire Parameters | ||

| Working fluid type | mm | Purified water |

| Maximum working fluid pressure | mpa | 6-10 |

| Working fluid protection | Automatic lifting enclosure | |

| Basic parameters | ||

| Rated power | kw | 3 |

| Input voltage | V/Hz | 380/50 |

| Outer dimension | kg | 2600 |

| Outer size | m | 2.6*1.8*2.3 |

| Packing size | m | 2.8*2.0*2.4 |

| Tank parameters | ||

| X-axis drive | Kingred custom servo motor | |

| Z-axis secondary lift | Electric | |

| System configuration | m | K-CUT integrated control system |

| Worktable surface | m | Granite worktable |

| Electrical control | kg | Kingred control system |

Kingred small hole EDM equipment features a fixed base and fixed worktable for maximum stability. This design ensures higher drilling accuracy, consistent performance, and longer machine life, giving customers reliable results with less downtime.

1 .Fixed base, fixed worktable, bullhead type structure.

Vibration Damping

Geometric Integrity

Long-Term Accuracy

2.Z-Axis Supported by Dual Parallel Guide Rails and Ball Screw

Speed with Accuracy

Reduced Positioning Errors

Higher Productivity

3.X, Y, and Z Axes Driven by Servo Motors

Precise Torque Control

Overload Protection

4.Original Taiwan Rotary Head

Radial Load Rigidity

Thermal Stability

Tool & Spindle Protection

5.Original Taiwan Air Pump

Stable Pressure/Flow

Efficient Debris Evacuation

Extended Tool Life

6.X,Y-Axis with High-Precision Linear Guide Rails, Low Noise, Long Service Life

7.Windows-Based Control System, DXF Files Readable via USB and Ethernet

8.21.5-Inch Industrial Touchscreen Display

1、Casting

Based on H250 international standard casting, Kingred developed metal ratio to improve casting rigidity and extensibility. All casting passed two times tempering and 3-6 months of natural aging treatment to release inner stress and decrease deformation.

H250 material + Unique rear metal.

Two times tempering/Natural aging treatment vibration aging.

Thoroughly remove internal stress.

High rigidity and stability.

2、Guideway

Sliver 1.5µm SP grade linear guideway realized high precisive position and repeated position to ensure machine height machining stability and precision, load rigidity.

1.5µm super precision.

Super stability and precision machining.

High-load rigidity.

Ultra-precision guideway.

1、Whole process manufacturing chain

Kingred builds complete manufacturing chain, have perfect manufacturing chain for machining(rough finish, finishing, superfinishing),precise assembly, electric engineering, machine debugging,and process engineering, and realizes to independently finish from part to complete machine. Quality is run through each manufacturing process, builds three system of quality trace for people, product,process, and ensure the stability and consistency of product.

Machining

Precise assembly

Electric engineering

Process engineering

2、Advanced manufacturing equipment

Kingred continually completes and innovates the infrastructure of manufacturing equipment, ensures that hardware is high precision, successively introduces an advanced industry machine for Mitsubishi 5-axis machining center, SNK machining center, DMG machining center, OKAMOTO grinding machine.Industry lead manufacturing hardware equipment is basic guarantee that Kindred's machine has high precision and best surface finish manufacturing.

Mitsubishi 5-axis machining center

SNK machining center

OKAMOTO grinding machine

DMG machining center

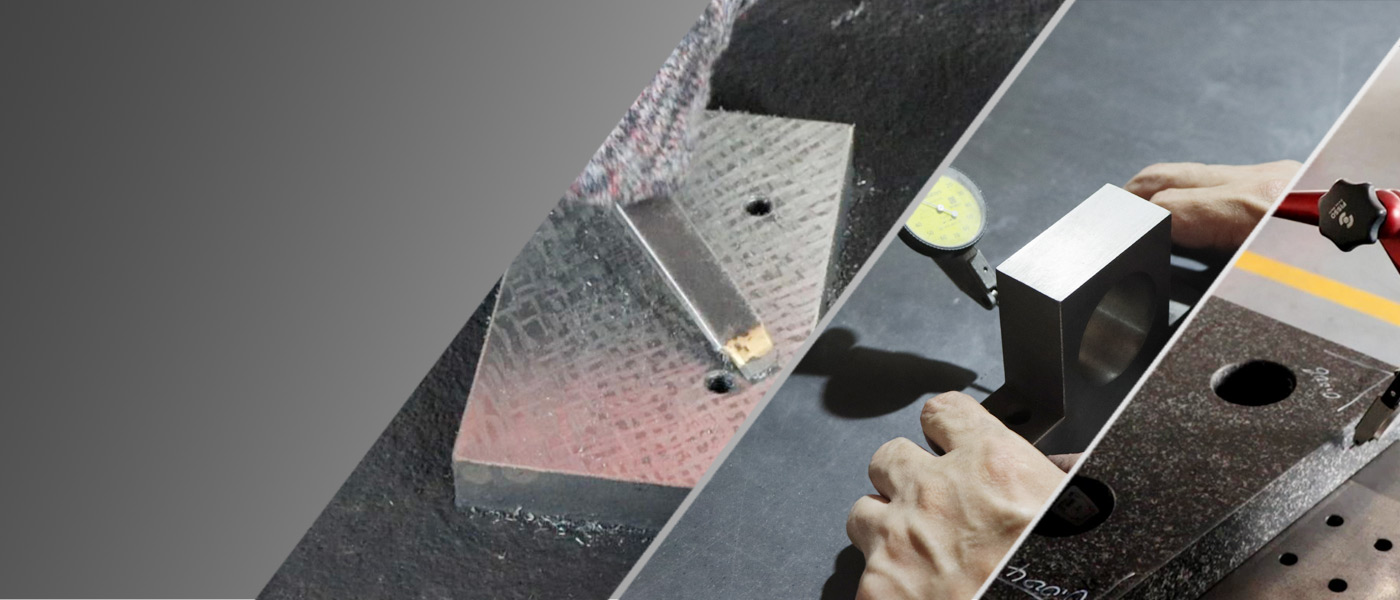

3、Precise measuring equipment

Kingred have double inspection for manufacturing process and outcome, high precision measuring equipment for API laser inferterometer, Switzerland TEST three-coordinate detector, Germany Planolith marble square, Japan Sanfeng roughness tester,etc realizes from part precision to machine dynamic precision, positional precision and precise test of manufacturing outcome.

Laser interferometer

Toughness tester

Double zero-grade marble ruler

Three-coordinate tester

4、Ingenuity manufacturing process

Kingred with 17-year manufacturing experience have some experienced manufacturing engineers that working age over 5 years. Keep on connecting traditional craft and modern precise equipment manufacturing, the key high-precision parts adhere to the manual scraping process to ensure that the machine has a stable step distance machining precision for many years.At the same time, the human-centered quality traceability system creates an ingenious manufacturing process.

17-year manufacturing experience

Traditional technology application

Quality traceability system

-

Kingred edm hole drilling machine KD630CNC

Kingred edm hole drilling machine KD630CNC -

Kingred Hole Drilling EDM machine KD430CNC

Kingred Hole Drilling EDM machine KD430CNC -

Kingred Precision CNC WEDM KD400ZL

Kingred Precision CNC WEDM KD400ZL

Customers make us achievement

We will create value for you