Suzhou Kingred Intelligent Equipment Co., Ltd.Overview

1. Our History

Kingred Intelligent Equipment (Suzhou) Co., Ltd. traces its roots back to Kingred (Huai’an), founded in 2007. After 14 years of steady growth and industry experience, the company was officially upgraded and rebranded as Kingred Intelligent Equipment in 2021, and relocated to 222 Zhongyun Road, Suzhou New District, Jiangsu, China.

2. What We Do

We focus on the full cycle of R&D, manufacturing, and application of intelligent EDM equipment. Our goal is to provide solutions that meet the changing needs of modern manufacturing.

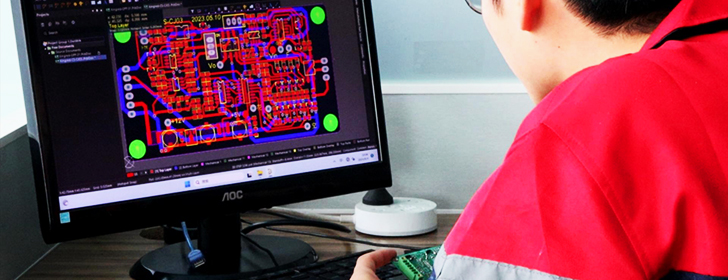

3. Innovation and R&D

Our professional R&D team continuously improves mechanical structures, electrical systems, and control software. In 2022 alone, we were granted 5 national patents. We also developed the K-Cut EDM system, which integrates motion control, data processing, and remote management into one platform.

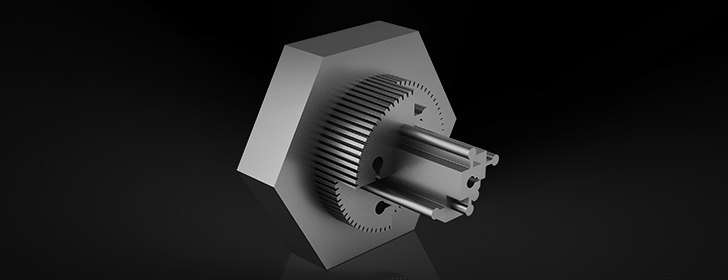

4. Manufacturing Capabilities

We operate a complete in-house machining chain, supported by industry-leading equipment such as:

Mitsubishi 5-axis gantry machining centers;

SNK gantry machining centers;

DMG machining centers;

OKAMOTO precision grinding machines

With these resources, we handle milling, grinding, boring, drilling, and more, ensuring end-to-end control of our manufacturing process.

5. Quality Assurance

Quality at Kingred is built on a three-pillar accountability system: people, processes, and products. We use advanced tools like laser interferometers, CMMs, and roundness testers to ensure precision. Real-time data monitoring allows us to trace quality at every stage, driving continuous improvement.

6. Customer Solutions

We deliver solutions through a four-phase cycle:

Discovery;

Conceptualization;

Implementation;

Refinement

This approach turns customer challenges into tailored hardware and software applications that maximize efficiency and return on investment.

7. Vision for the Future

Looking ahead, Kingred is advancing smart manufacturing through digitalization, intelligent data management, and flexible production systems. By connecting machines, processes, and insights, we are building a future-ready manufacturing ecosystem.

Kingred

R&D Manufacturing Application integrated Eco-manufacturing chain

R&D

Kingred has built a complete R&D system covering mechanical design, control software, and electrical technology. We have developed innovative mechanical structures and created the K-Cut software series with independent intellectual property rights. On the electrical side, our breakthroughs include high-frequency discharge, PLC control, high-speed cutting, auto-threading and precision machining technologies.

Manufacturing

Kingred operates a fully integrated production line, capable of handling material machining, machine assembly, electrical assembly, and testing. To ensure world-class precision, we have introduced advanced machining and inspection equipment.

Application

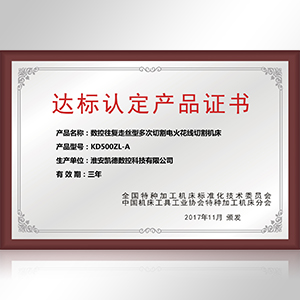

Customer success is our core goal. Kingred has developed machine models for precision cutting, high-speed cutting, taper cutting, and heavy-load machining. By offering flexible manufacturing and customized solutions, we continuously meet diverse customer needs and create real value in application.

Honor

Knowledge-Driven Tech, Tech-Driven Value Creation

Development History

Cumulative experience and concentrative development make value more valuable

0Y

Focus on WEDM

Kingred established

0Y

R&D

Own developed WEDM launched

0Y

Integrated model

ZL series WEDM launched

0Y

Software ecology

K-cut EDM system

0Y

Solutions

Kingred Intelligent established

0Y

Manufacturing upgrade

Input Mitsubishi 5-axis high precision equipment

Partner

Cooperative Partner

众多客户信赖和选择,见证实力